Filterpress Magnum Perfect for extremely huge plants worked in totals, earth and rock treatment in quarries and mines….

To get impeccably dried mud cakes, Matec America channel press is the best specialized/affordable arrangement. What the majority of contenders can’t offer their clients and the fundamental element of the progress of Matec channel press is the high tension innovation. Matec organization is accomplished in the assembling of channel press, to that end we can offer machines which highlight the best quality/cost proportion.

It is feasible to introduce moving cutting edges in the channel press to decrease protection from stream of fluid through the slurry.For the cycle preceding cake release, air blowing is utilized for cakes that have penetrability of 10−11 to 10−15 m2. In the beginning of press use in the metropolitan waste biosolids treatment industry, issues with cake adhering to the fabric was hazardous and numerous treatment plants embraced less compelling axis or belt channel press advances. From that point forward, there have been extraordinary improvements in texture quality and assembling innovation that have made this issue out of date. Not at all like the US, programmed layer channel innovation is the most widely recognized technique to dewater metropolitan waste biosolids in Asia.

When the channel chambers are stacked with slurry, the channel plates are constrained along with water powered rams that produce pressures ordinarily in the locale of 100 pounds for every square inch. The roll channel medium loosens up into a channel compartment which closes around the medium and becomes compressed via air and grimy coolant siphoned into the compartment. The coolant is sifted through the medium until the cake develop is to such an extent that the stream rate turns out to be too low or the tension drop turns out to be excessively high. The chamber then, at that point, opens and new medium is progressed into the chamber for the following filtration cycle.

Since each plate includes a recessed region, when the plates are pushed together, they structure a chamber in which solids gather on the channel fabrics. Plate and casing channel press comprise of on the other hand organized channel plates and edge to frame a bunch of channel chambers. The outer layer of the channel plate is notched, and the projecting piece of the channel plate is utilized to help the channel fabric. The edge and corner of the channel outline and the channel plate have through openings, which structure a total channel after get together, and can enter suspension, wash water and channel filtrate. Each side of the plate and the casing has a handle upheld on the cross bar, and the plate and the edge are squeezed by the pressure gadget. The channel material between the plate and the casing goes about as a fixing gasket.

A major advantage that channel press makers offer with their film channel plates is that an exceptionally serious level of dewatering is conceivable with this innovation. The process duration of filtration by normal additionally gets decreased by practically half, contingent upon the degree of suspension. What this outcomes in is quicker completion times and filtration times.

Moreover, expanding request across the auto business is expected to support the development of the market too. You ought to constantly heat up your French press before you start by filling and exhausting it with high temp water, so energy isn’t squandered warming it up. Earthenware will in general emit a great deal of intensity ; glass, metals, for example, steel and plastic are better protectors. This plastic French press has a limit of one liter and makes 8 little cups.

Contingent upon the idea of the slurry being dewatered, the span between siphon strokes at terminal tension is seconds. Different boundaries incorporate the thickness of the channel cake, the greatest feed pressure which the slurry is taken care of to the press, and the channel fabric choice. While channel presses are extraordinary bits of dewatering hardware, they are best utilized on a slurry comprised of about percent solids. Lower solids focus requires running the water through a clarifier first. What’s more, you can utilize extra frameworks, for example, material washing frameworks, trickle plate, and cake safeguards to additional increment channel press execution and usefulness.

Without a channel press or comparable bits of dewatering gear, a settling lake is in many cases the primary choice for water treatment. In addition to the fact that lakes require a lot of land to utilize, however they likewise lose their capacity to clean water over the long run as the solids that you eliminate develop in the lake water. This gives lakes an ominous how does a filter press work long haul ROI as messy water will ultimately begin returning into your cycle except if you dig the lake or make another lake. At ChemREADY, we educate the utilization concerning a channel press and other dewatering gear over a lake in many applications.

The upper platten lifts, the dry cake is carried out on the channel paper and into a container.

Water driven chambers on every one of the four corners keep the channel pack shut while in the pressure stroke. MDC-series is a natural slop dehydrator in which the element of multi-circle dehydrator is added on the guideline of the screw press dehydrator. The chamber screen, that consolidates the screw shaft, is included …

The taking care of siphon quits siphoning the suspension into the channel press chambers. Our appreciation likewise goes to Robert Pillers for assessing the channel press in headway and making valuable data sources that prompted a few changes. Metso Outotec’s filtration mastery is based on very nearly 100 years of R&D and process information, and is upheld by the organization’s universally extraordinary Dewatering Technology Center in Lappeenranta, Finland. The DTC assumes a critical part in Metso Outotec’s filtration arrangement developments and goes about as a center point for close college collaboration connected with detachment innovation research. Metso Outotec has performed north of 14,000 filtration tests and has conveyed more than 5,000 channels all over the planet. Support, closures and fixes Trust the individuals who realize the gear best to guarantee that your creation objectives are met.

The synthetic likewise supports permitting the water to set free from the strong material. A variable which influences the filtrate stream rate is the cake thickness which is being created. The cake thickness alludes to the distance between the channel fields of contiguous channel plates inside the shut offices of the channel pack.

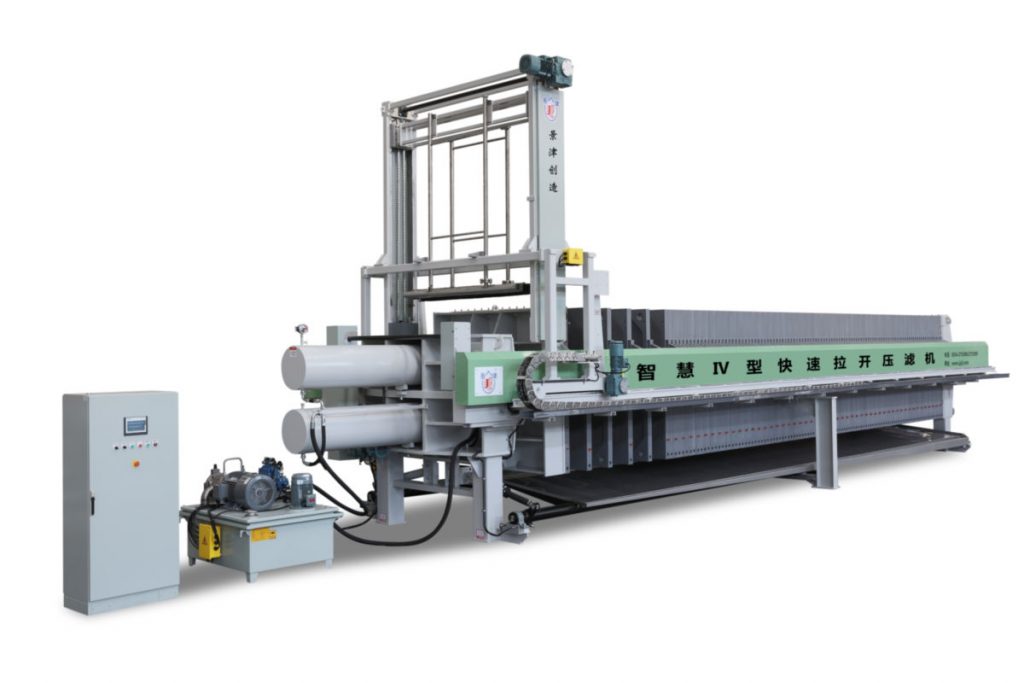

Siphon Necessary to make the strain which drives the cycle, it is typically a positive removal siphon or a radial feed siphon. Conclusion System-A water driven smash is utilized to press the plates together and keep the channel intact during activity. Fixed Head-The side of the edge without the conclusion framework has a head that lines up with the channel pack. It has a feed opening for the slurry to enter and deplete opening for filtrate to exit.

Press channels generally used to dry slime are of the simple automation plaques type for the release of the tortas. The press channel is the main gear which ensures exceptionally high viable tensions , with which greatest dryness of torta is accomplished. Flocculation happens when undermined particles are united by high sub-atomic weight polymers like Polyacrylamides. These polymers genuinely structure a scaffold between at least two particles, joining the solids into free three-layered structures. These designs are both denser and more permeable than the untreated solids thus help in the run of the mill/normal types of mechanical dewatering utilized. Sidebar development, channel plate size range accessible from 250 mm x 250 mm to 1500 mm x 2000 mm.