Here are some ways pumps typically contribute to industrial system efficiency:

- Energy Efficiency:

- Modern pumps are designed with a focus on energy efficiency. They may incorporate advanced motor technologies, efficient impeller designs, and variable speed controls to optimize energy consumption.

- Variable Speed Operation:

- Pumps equipped with variable frequency drives (VFDs) allow for variable speed operation. This enables the pump to match the demand of the system, reducing energy consumption during periods of lower demand.

- Precision Control:

- Pumps that offer precise control over flow rates and pressure contribute to efficient system operation. This is particularly important in processes where maintaining specific conditions is crucial.

- Smart Control Systems:

- Integration with smart control systems and industrial automation platforms allows for real-time monitoring and control. Smart systems can optimize pump operation based on changing conditions and demands.

- Predictive Maintenance:

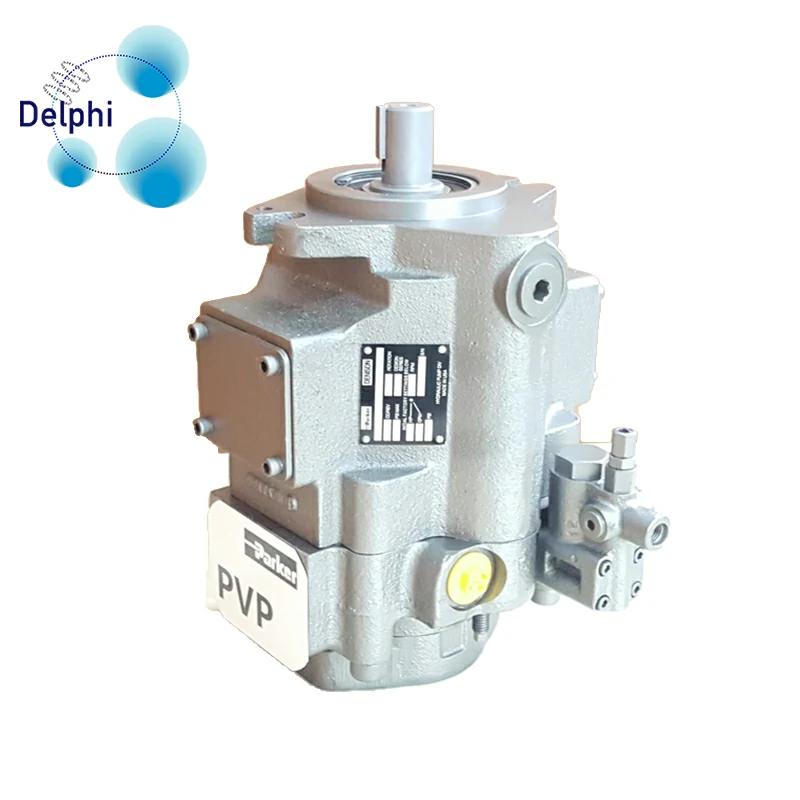

- Pumps with predictive maintenance features use sensors and monitoring systems to detect potential issues before they lead to pump failure. P3 Series Pump manufacturer This proactive approach minimizes downtime and enhances overall system reliability.

- High Efficiency Motors:

- The use of high-efficiency motors in pumps contributes to reduced energy consumption and lower operating costs.

- Material Selection for Longevity:

- Pumps designed with durable and corrosion-resistant materials ensure a longer lifespan, reducing the frequency of replacements and associated downtime.

- Optimized Hydraulic Designs:

- Efficient hydraulic designs, including well-matched impellers and pump casings, enhance overall pump efficiency, reducing energy losses and improving performance.

- Ease of Maintenance:

- Pumps that are easy to maintain, with quick access to key components and minimal downtime for maintenance activities, contribute to overall system efficiency.

- Compliance with Energy Standards:

- Pumps that comply with international energy efficiency standards contribute to sustainability efforts and may qualify for energy efficiency incentives.

- System Integration:

- Pumps that seamlessly integrate into larger industrial systems and processes contribute to overall system efficiency by ensuring smooth operation and coordinated control.

- Reduced Noise and Vibration:

- Pumps designed with features to minimize noise and vibration contribute to a safer and more comfortable working environment.

- Compact Design and Footprint:

- Compact pump designs with a smaller footprint can be advantageous in installations where space is limited, contributing to efficient use of facility space.

To understand how the P3 Series Pump specifically contributes to the overall efficiency of industrial systems, it is recommended to refer to the product documentation, technical specifications, and any efficiency-related features highlighted by the manufacturer. Additionally, consulting with the manufacturer or industry experts can provide more detailed insights into the pump’s performance and efficiency characteristics.